Machinist I

Program Type: Certificate in Applied Science

Program Level: UG

Division: Career & Technical Education

Program Duration: 12 months

Program Contact: Shawn Reed

Credit Requirement: 29

Time: Day

Program overview

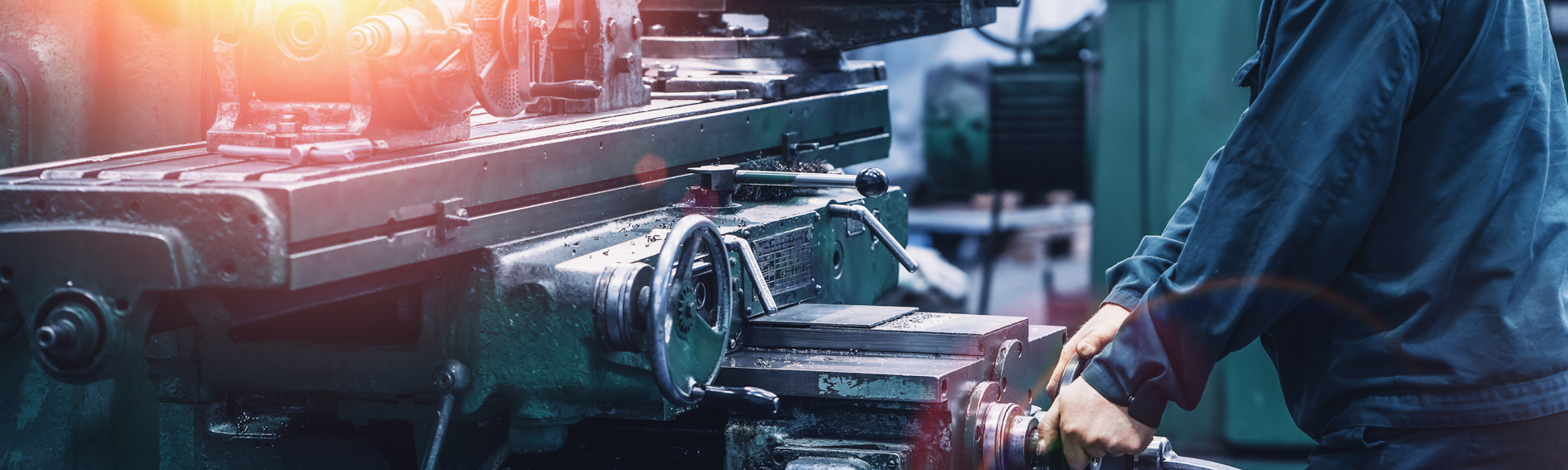

This certificate provides an individual with the basic skills for manual machine operation, including: safety, tooling, set up, speeds and feeds, materials, print reading, and precision measurement. The student will focus learning activities on engine lathes and milling machines. Certificate completers will be prepared for entry level machine tool positions in manufacturing and service businesses.

Courses Required

- Choose an option

Entry Requirements

To see a list of entrance requirements for this program, please check the FDTC Course Catalog.

Student Learning Outcomes

Graduates of this program will be able to:

• Apply industry standard safety practices and specific safety requirements for different machining operations.

• Interpret blueprint information and translate into actionable items.

• Perform setup and operation of manual machines, such as band saw, lathe, mill, and drill press.