FDTC Facilities, SiMT Manufacturing, and Stratasys Recognized for Innovation

Florence-Darlington Technical College’s (FDTC) Facilities and SiMT Manufacturing teams, as well as, collaborative partner Stratasys were recently honored as nominees for the prestigious A. Wade Martin Innovation Team of the Year Award at the SC Technical Education Association (SCTEA) annual conference.

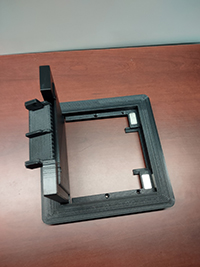

The recognition stemmed from the SiMT Manufacturing team’s creative problem-solving approach to replacing an aging in-floor electrical receptacle box in one of the college’s buildings. When the Facilities department sought a replacement, an electrical contractor informed them that the part was obsolete and would require extensive and costly renovations, estimated between $16,000 and $30,000, to replace.

Rather than accept the high costs and disruption, the Facilities and SiMT Manufacturing teams collaborated to find an innovative solution. After assessing the issue, they devised a way to 3D-print a custom replacement part, eliminating the need for major construction work.

“3D printing allows for highly customized parts tailored to specific needs, whether for medical devices, consumer goods, or industrial components,” SiMT Director of Manufacturing Operations Jonathan Melton said. “In this case, our team’s creativity and technical expertise enabled us to replace a discontinued part and save the college from costly renovations.”

By leveraging advanced manufacturing technology, the SiMT team successfully designed and printed a new electrical receptacle box, which Facilities installed. This cost-effective, practical solution provided a long-term fix while significantly reducing expenses.

Adding to the savings, Stratasys, a SiMT Manufacturing partner, provided the materials for the project at no cost. A Stratasys representative highlighted the value of collaboration:

“We are honored to support educational partners such as Florence-Darlington throughout the country,” Jesse Roitenberg, North American Education Manager for Stratasys, said. “Our exceptional relationship with SiMT Manufacturing and the college also provides us with an opportunity to help grow the next generation of 3D printing technicians.”

Through innovation and creative problem-solving, the group demonstrated how cutting-edge technology can be used to tackle real-world challenges—earning them well-deserved recognition.